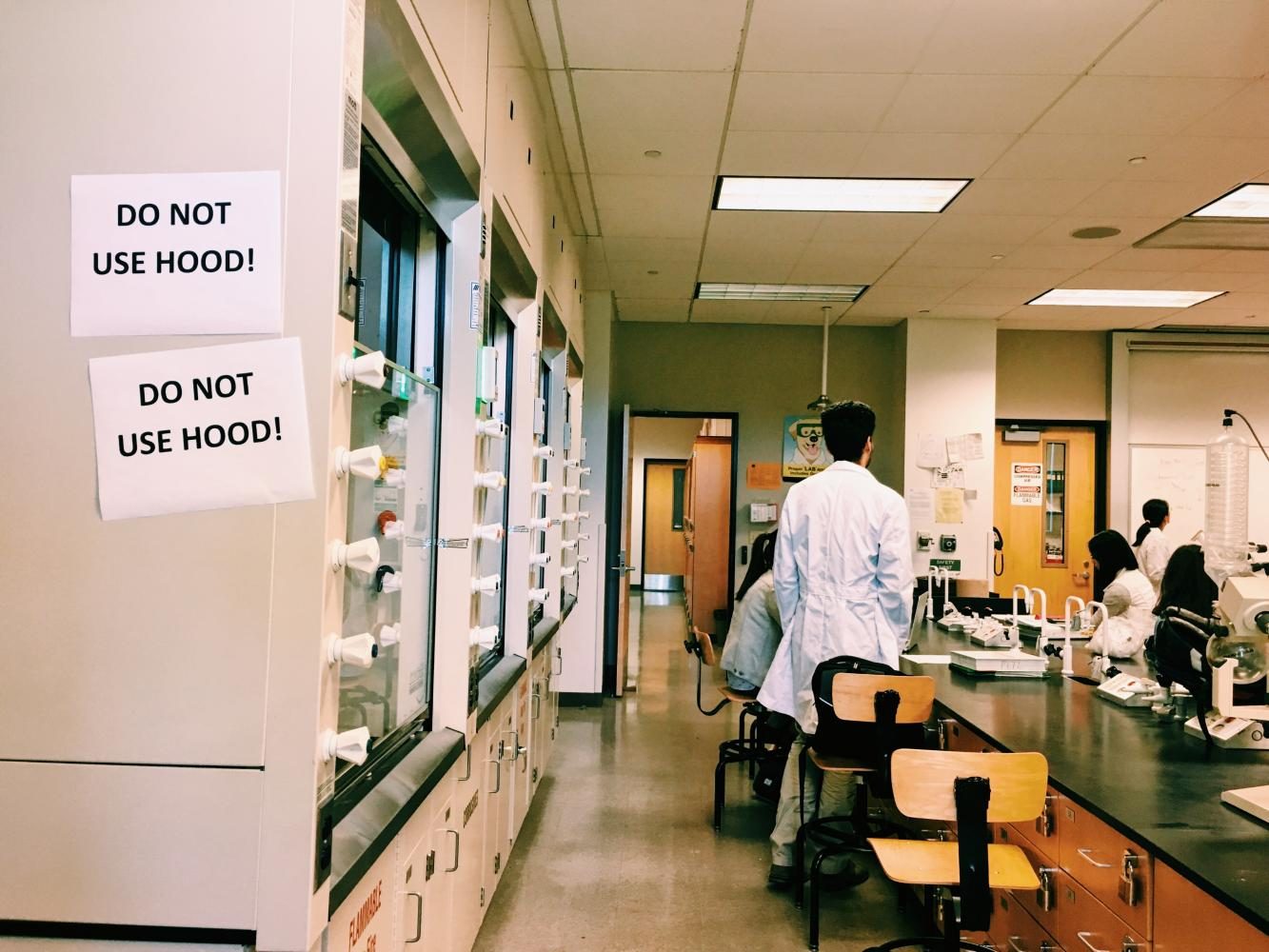

Students and faculty were potentially exposed to hazardous chemicals because of broken fume hoods in the Science Building between 2015 and October 2016, before they were repaired last week.

This comes seven months after students and chemistry staff discovered, by chance, a broken hood during a lab experiment back in October 2016.

“There was no communication from the administration at all regarding those stickers having changed status,” Chemistry professor Dr. Iyun Lazik said of the hoods that were broken. The said stickers indicated the hoods were “not certified” meaning they failed inspection.

Lazik said after discovering numerous hoods were broken in October 2016, the chemistry department held an emergency meeting and wrote a letter to administration to let them know they had not been informed and to ask what the status was for getting the hoods fixed.

Fume hoods protect users from breathing in hazardous fumes produced by chemicals by drawing the air up into the vent and exhausting them outside the building. The flow rate of air is adjusted in conjunction to the pressure to maintain a safe parameter of airflow. Toxic chemicals breathed in during when released could cause immediate to long-term health problems.

“It turns out that some of the hoods were broken since 2015 and they had failed inspection then.” Lazik said. “Administration was aware of that because they had sent out a spreadsheet denoting which ones were inspected and which ones had failed. We had to request it (the spreadsheet),” Lazik said.

Lazik said maintenance disconnected the fume hood alarms sometime between the 2015-2016 academic years because one of the fume hood alarms was going off constantly.

“That’s when we knew the alarm was off. So we stopped using that hood. But for all the remaining ones the alarms did not go off even though they failed OSHA inspection,” Lazik said.

The problem is that the alarms are supposed to go off when the flow rate is low so we don’t have to rely on the stickers, but none of the alarms went off, Lazik added.

“We work with toxic fumes. Especially in organic chemistry there are potential carcinogenic compounds that we breathe,” Lazik said. “We were under the assumption that we were being protected and if the flow rates were as low as they were it means we were breathing all of those toxic chemicals.”

“Safety is at the forefront and student’s well-being is a top College interest.” Jorge Escobar, Vice President of Student Services wrote in an email in response to concerns about potential exposure to harmful chemicals.

“It’s my understanding that the overall ventilation system was working at a capacity that would have not exposed students, faculty or staff to harmful chemicals,” Escobar said.

Pre-med student Karyna Brandariz said she felt it was dangerous during the first lab experiment of the semester where in her chemistry lab only two of the four fume hoods were working.

“The first lab we were all huddled together and took turns using them (fume hoods). We were really close to one another. We were worried things were going to spill over,” Brandariz said.

“Health is a priority. It’s worrisome when we have to open the doors. That’s the only ventilation that we have,” Brandariz said. “We’re inhaling all this stuff and its spilled on me before and its pretty strong stuff because I have gotten chemical burns without realizing what has happened.”

Supervisor for the district maintenance department Anthony Jakubowski said that the exhaust connected to all the fume hoods in the building has always been working despite the hoods labeled “not certified.”

The fume hoods are complex, Jakubowski explained. They are connected to multiple other units that feed information. Calibration can get off and that’s when the hoods fail inspection. But they still suck up air because of the exhaust.

Maintenance jumped on the issue as soon as they got the Technical Safety Services report regarding the broken hoods, Jakubowski said. He did not specify when the report was issued.

Aside from the health issues, providing students with adequate space and equipment for their curriculum was another concern Lazik addressed to a group of faculty members during an Academic Senate meeting on April 18.

“The problem is we continue to have maximum capacity (of students) and yet we don’t have the facilities to sustain that,” Lazik said.

When there is a lack of equipment or facilities, student class size is supposed to be reduced and reflected in the registration system when students register for classes. However, spring 2017 semester the class sizes were not reduced nor reflected in the registrar prior to the beginning of the semester, Lazik said during the meeting.

“I feel like having the vents are important so that we can get what we need to get done so we can learn the material,” chemistry student Brandariz said. “If they expect us to get these labs done we should have the equipment and the tools to get them done safely.”

Other students shared Lazik’s and Brandariz’s frustrations.

“My main concern is time wise,” said neuroscience major Madison Kite. “It’s hard especially because we’ve been using the hot plates under the fumes so trying to get everyone’s experiments there’s only so many you can fit in there.”

During this same meeting, Owen Letcher, director of Facilities and Bond Programs Management for the San Jose Evergreen College District also discussed the status of the fume hood repairs and answered questions.

“Two of the hoods do not comply with the face velocity testing that is required. Three have other issues with the alarm control system,” Letcher said at the April 18 Senate meeting.

Action was taken in October 2016 by the district to fix the broken fume hoods.

“August 2016 when the report came out again those were distributed and that began this cycle,” Letcher said at the meeting. “We had discussions on how to correct this and what can be done to not put anyone at risk.”

The district, however, did not address the issue of the broken fume hoods dating back to 2015.

“I would like to clarify on the timelines of October 2016 because that is not true since the hoods failed ahead of that time,” Lazik interjected at the meeting. “The only reason you are able to say October 2016 is when the chemistry department sent out the letter. In fact the hoods failed, some of them since 2015.”

“I would really like the district to address that problem because there was no notification done and we were all working under hazardous conditions,” Lazik said at the meeting.

Letcher said he could not answer the question because he did not become a district employee until November 2015.

“We will ensure folks are informed of any future situations with the hoods to avoid having a similar situation.” Escobar said in an email regarding the notification issues.

Letcher stated that the district is moving forward with a project to replace the valve actuator and control systems throughout all the hoods in the building.

“The current system is only serviced by one outside vendor and the original equipment manufacturer has changed design,” Letcher wrote in an email.

Due to limited availability of parts the hoods were unable to be repaired in as timely a manner as faculty would have liked Letcher wrote.

“Working with this one vendor has been a challenge for us,” Letcher had said during the senate meeting.

A plan is already in motion to begin replacing the fume hood systems to ensure more timely repairs and access to parts. Letcher said we will have a more robust response plan to testing protocol. It will be implemented in phases to avoid shutting the science building down for a long period of time and to reduce impact on student learning.

The extent of the potential health risks involved from exposure to the broken hoods is unknown.

“Carcinogenics has long-term effects. The longer you’re exposed to it the more accumulation you have and then you have problems,” Lazik said. “If you look at the material safety data sheet of all the chemicals we worked with we’re talking about central nervous system damage, liver damage, and lung damage.”

“Because it’s unknown how long we’ve been exposed, even though we do know the chemicals we were being exposed to, it’s hard to address and assess how harmful that was,” Lazik said.

Another chemistry faculty member was contacted for comments but she referred the Times reporter to Lazik.

“I made a joke earlier that I have been sick the entire semester,” Lazik said after coughing, “that it could be because we were exposed to all of those chemicals and no one knows for sure.”